Three revolutionary synthetic materials

16 October 2020

Plastic products offer undoubted advantages over many of their analogues in wood, metal or other materials. In fact, they have a longer life, resist wear and weathering, and can be easily recycled. Some of them also have incredible mechanical strength, in some cases superior to steel.

Structural plastic lumber

Structural plastic lumber is a lightweight and durable "super-plastic" material, capable of supporting the weight of a 120-ton locomotive.

His design was developed from experiments by Professor Thomas Nosker of Rutgers University in New Jersey who had used recycled PET containers, high-density polyethylene layers and polystyrene.

In the United States this material is already used for urban furnishings, bridge beams in some military bases, and railway sleepers crossing protected natural areas.

In addition to solving the problem of wear over time, according to estimates made, its use has saved 300 thousand tons of plastic over a few years.

Graphene

Graphene is one of the strongest lightweight materials ever conceived by man, with a resistance 10 times higher than that of steel.

His invention derives from research by Professor Markus Buehler, Director of the Department of Civil and Environmental Engineering at the Massachusetts Institute of Technology.

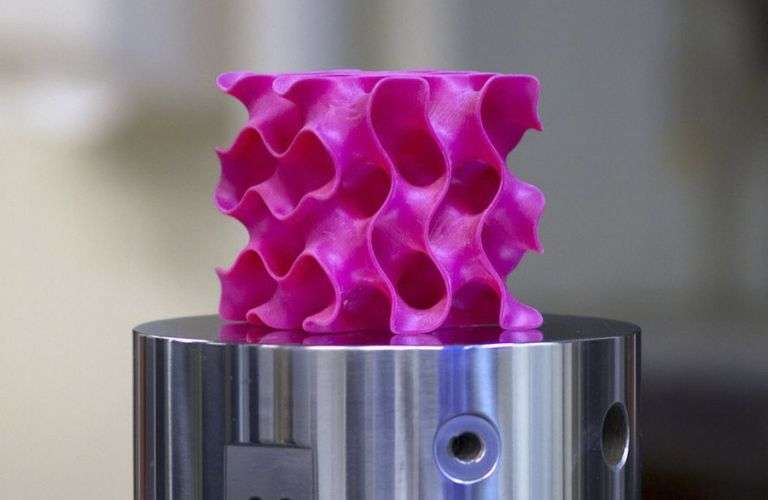

Its structure, composed of thin sheets of carbon atoms under strong pressure, resembles that of a sponge. This shape, having a very large surface compared to the volume, is incredibly resistant and light.

According to Professor Buehler, the behaviour of this material can be compared to that of ordinary paper, which when it is in single sheets, can be easily crumpled but, rolled to form a tube, becomes much more resistant. The same thing happens with the geometric arrangement of graphene sheets that form a very strong configuration.

Thanks to the particular spongiform structure, the researchers indicate as potential application of this material especially the construction sector, some filtration systems for water or chemical transformation.

Polyethylene and mother of pearl

Recently, researchers at Buffalo University, funded by the US Army Research Department, created a plastic that is 14 times stronger and eight times lighter than steel

This material is derived from ultra-high molecular weight polyethylene (UHMWPE), already used to make products such as bone prostheses and common guitar picks, and during its design the researchers were inspired by the structure of the mother-of-pearl of sea shells.

This gives the material an extremely resistant outer surface and a more flexible internal support able to deform and absorb the blows.

"The material is stiff, strong and tough. It could be applicable to vests, helmets and other types of body armor, as well as protective armor for ships, helicopters, and other vehicles. [. ] In contrast to steel or ceramic armor, UHMWPE could also be easier to cast or mold into complex shapes, providing versatile protection for Soldiers, vehicles, and other Army assets".

Dr Shenqiang Ren, Department of Mechanical Engineering and Aerospace.

Source:

https://www.sciencedaily.com/releases/2016/07/160707140229.htm

https://scitechdaily.com/new-material-14x-stronger-8x-lighter-than-steel-may-lead-to-next-gen-military-armor/

https://news.mit.edu/2017/3-d-graphene-strongest-lightest-materials-0106

Cover: The structure of 3D graphene - photo by Melanie Gonick (MIT)

WE PRODUCE HIGH QUALITY POLYETHYLENE PRODUCTS FOR

CIVIL AND INDUSTRIAL USE